Heavy Equipment

7 Types of Rollers for Construction Works

A quick overview of the most popular roller machines.

Rollers are heavy construction equipment used for compaction of soil, concrete, gravel, crushed stone or asphalt on the surface of construction sites.

They are mainly used in road construction and creation of compact foundations in large construction sites and rely on their weight to compress the surface they are working on in combination with other mechanisms such as vibration and kneading.

There are various types of rollers used in compaction works with the choice depending on the job and material to be compressed. These include: –

Smooth Wheeled Rollers

Also known as static rollers, smooth wheeled rollers are made up of one steel drum in front and one or two at the back.

They are mostly used on soils that do not need a lot of pressure for compaction especially gravel, asphalt, crushed rock and well graded sand.

The performance of smooth wheeled rollers can be increased by filling the steel drums with water or concrete which increases their weight.

There are two types of smooth wheeled rollers: single drum rollers and double drum rollers.

1. Single Drum

Single drum rollers are among the most common types of heavy equipment.

They are usually fitted with a steel drum in the front and two special wheels at the back to prevent flat tire mishaps.

Single drum rollers can operate in restricted spaces thanks to their small sizes. The machines are ideal for creating foundations as well as paving roads and sidewalks.

However, due to the added weight in the front, these rollers cannot roll over some surfaces.

2. Double Drum

Also known as tandem roller, a double drum roller is fitted with one steel drum in the front and one at the back. The roller usually moves forward as the two drums begin to move.

Double drum rollers are very efficient machines capable of flattening and paving entire sections of a road within a very short time.

These rollers operate well on flat or gradual surfaces such as asphalt. However, since they have little traction, single drum rollers are not suitable for specialized tasks.

3. Vibratory Rollers

These rollers are variations of the smooth wheeled roller (both the single and drum roller) characterized by an internal eccentric shaft that causes them to vibrate.

They usually vibrate as the machine compacts and flattens the surface.

Vibratory rollers have better compaction capabilities compared to the static smooth wheeled rollers since the vibration causes the rearrangement of particles closer together, which results in reduction of air voids and increased densification of the surface.

RELATED: Most Powerful Road Construction Equipment

4. Sheepsfoot Rollers

Sheepsfoot rollers, which are also known as padfoot or tamping rollers, consist of a steel drum with circular or rectangular shaped protrusions or feet.

The feet aid in kneading the surface to get rid of empty voids.

Sheepsfoot rollers are mainly used for compacting soil and silty clay in road construction projects. They are best suited for cohesive or fine-grained soils such as clay soils.

The weight of the steel drum can be increased by mounting steel sections on to it, or by ballasting the drum with water and damp sand to provide more contact pressure.

5. Pneumatic Rollers

Also known as pneumatic tyred roller, a pneumatic roller is a type of large, ride-on roller with two or more rows of four to six closely spaced tyres.

They are used in the compaction of uniform loosely compacted soil and are perfect for pavement subgrade work in the construction of highways and dams.

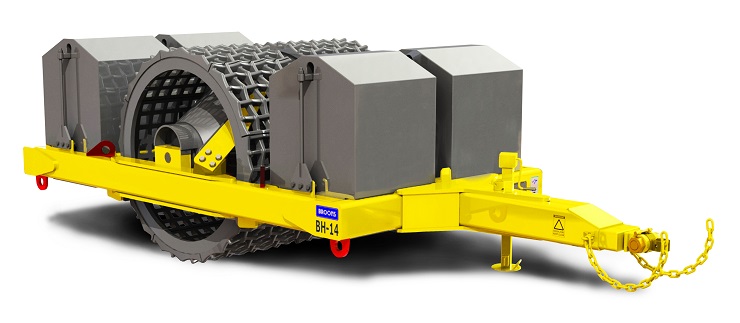

6. Grid Rollers

Grid rollers consist of a cylindrical surface made of a network of heavy steel bars which form a mesh with square gaps.

They are used for the compaction of well graded coarse soils and weathered rocks.

The grid can be ballasted with concrete blocks or steel attachment for better compacting efficiency.

7. Cylindrical Rollers

Cylindrical rollers are lightweight walk-behind rollers that are pushed by an operator, although they are sometimes powered by an engine.

Cylindrical rollers are mainly used for small developments such as yard projects. They are usually 1 meter in diameter and are often made of iron, concrete, or stone.